STRUCT GUARD-CARBON

Satisfied Tensile Strength & Elongation according to ASTM D 3039

- View in video

Product Rating

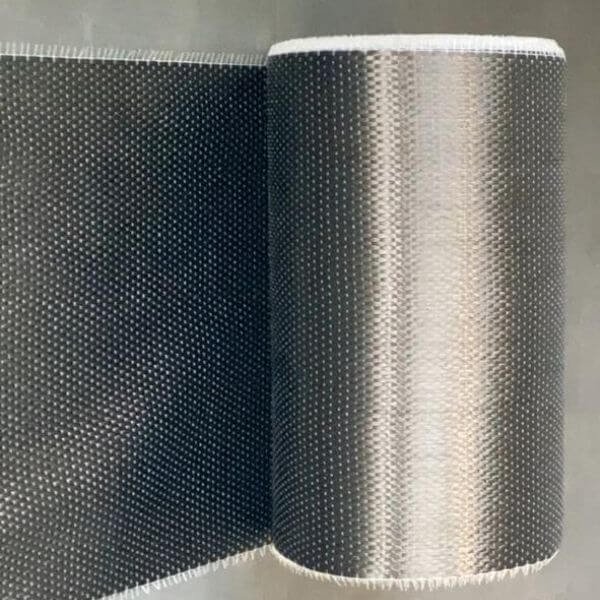

Unidirectional Carbon Fibre Sheet

STRUCT GUARD – CARBON is a Fiber Carbon Sheet Used for the Structural Strengthening of beam columns applicable with STRUCT GUARD- PRIMER and STRUCT GUARD- SATURANT. GSM: – 230 GSM, 330 GSM, 430 GSM, 630 GSM, 930 GSM

Carbon fiber is commonly more potent than stell, in particular when thinking about power-to-weight ratio. While steel is known for its excessive strength and stiffness, carbon fiber offers advanced strength in line with unit of weight. This makes carbon fiber sheet material is ideal for packages wherein weight reduction is vital without sacrificing strength

Product Brochure

Additional Information:

| Fabric Type | Unidirectional |

|---|---|

| Roll Width | 500 mm |

| Roll Length | 50-100 mtr |

| GSM | 230, 330, 430, 530, 630, 930 |

| Density | 1.56 g/cm³ |

| Weft | Glass Fibre (Thermo Fixed) |

| Wrap/Grade | 12K, 24K |

- High Tensile Strength – Provides up to 5000 MPa tensile strength, making it ideal for heavy-load applications.

- Superior Corrosion & Chemical Resistance – Does not corrode like steel, ensuring long-term protection in harsh environments.

- Lightweight & Non-Intrusive – Adds minimal weight to structures, making it perfect for retrofitting and repairs.

- Seismic Strengthening – Helps improve structural integrity in earthquake-prone areas.

- Easy Application & Versatile Use – Can be applied on concrete, steel, and masonry structures with Struct Guard Primer & Saturant.

- Cost-Effective & Low Maintenance – Reduces repair frequency and long-term maintenance costs

- Beams

- Chimneys

- Columns

- Pipes

- Slabs

- Structural connections

- Tanks

- Flat slabs and walls can also be strengthened by wrapping with carbon fibre additional

Why Indian Infrastructure Chooses Carbon Fiber Sheet?

- Strengthening beams, columns, slabs, and bridges

- Seismic retrofitting in earthquake-prone zones

- Repairing corroded or cracked concrete structures

- Preventive reinforcement during renovation

- Upgrading industrial plants and public utilities

With rising regulatory pressure, ageing infrastructure, and unpredictable climate styles, smart builders and engineers are making an investment in preventive strengthening techniques. Carbon fiber wrapping ensures peace of mind—sponsored by way of international standards and tested subject performance.

If you are looking for the best carbon fibre wrapping of columns or reliable Carbon Wrapping for Slabs constro Chem India Is leading and trusted carbon fiber sheet manufacturer in India. Our premium carbon fiber sheet are the best option for retrofitting, repairing, and prolonging the life of existing buildings because they offer exceptional strength without adding extra weight. Making them the ideal choice for retrofitting, repairing, and extending the life of existing structures. Whether it’s a commercial, or industrial project, our carbon fibre wrapping systems are trusted by engineers and contractors across India for their long-term performance and cost-effectiveness.

Frequently Asked Questions (FAQs)

What is Struct Guard Carbon UD and how does it work?

What are the main applications of Struct Guard Carbon UD?

Bridges, industrial buildings, chimneys, storage tanks, marine constructions, and historical restoration projects all use this high-performance carbon fiber technology. It facilitates seismic retrofitting and load-bearing augmentation.

What are the advantages of using Struct Guard Carbon UD?

- Enhanced Load-Bearing Capacity – Increases structural strength without adding significant weight.

- Corrosion and Erosion Resistance – Protects against environmental damage and prolongs lifespan.

- Lightweight and High Strength – Offers superior tensile strength (up to 5000 MPa) with minimal weight addition.

- Easy Application – Can be applied over existing concrete and steel structures with Struct Guard Primer and Saturant.

- Long-Term Durability – Reduces future maintenance and repair costs

How long is the curing and shelf life of Struct Guard Carbon UD?

If kept in a cold, dry location, the product has a 12-month shelf life. Although the ideal cure period varies according on the surroundings, full vigor is usually reached in a few days.